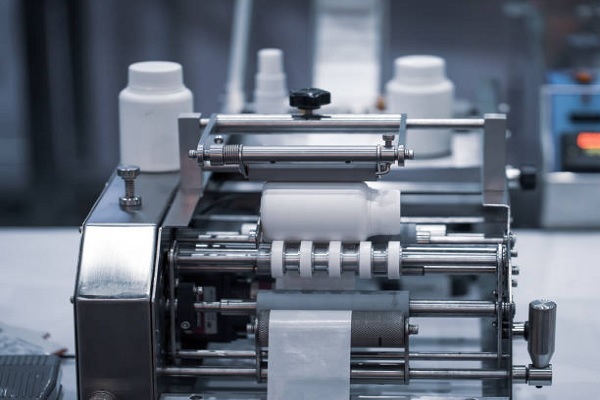

In today’s fast-paced industrial landscape, optimizing efficiency and ensuring precision are key elements in any production process. Automatic labeling machines have emerged as a game-changer, streamlining labeling tasks across various industries. These cutting-edge devices have not only revolutionized the packaging and manufacturing sectors but have also significantly impacted logistics, pharmaceuticals, and food industries, among others. In this article, we will explore the different types of labeling machines and shed light on what makes automatic labeling machines truly unique.

Types of Labeling Machines

Pressure-Sensitive Labeling Machines

Pressure-sensitive labeling machines are versatile and widely used for applying self-adhesive labels to various products. These machines utilize a combination of pressure and a label dispensing system to ensure accurate and smooth label application. They are ideal for curved surfaces, bottles, jars, and irregularly shaped containers. However, these machines may not be suitable for high-speed production lines, as they require precise label alignment.

Sleeve Labeling Machines

Sleeve labeling machines offer a seamless and visually appealing solution for labeling products with shrink sleeves. These machines apply heat to shrink the label around the product’s container, creating a 360-degree, tamper-evident seal. Sleeve labeling machines are commonly used in the beverage industry for labeling bottles and containers of different shapes and sizes.

Wraparound Labeling Machines

Wraparound labeling machines are specifically designed for high-speed production lines, where efficiency is crucial. They apply wraparound labels to products, covering the majority of the product’s surface. These machines are often used in the pharmaceutical and cosmetics industries to label cylindrical containers rapidly and accurately.

Print and Apply Labeling Machines

Print and apply labeling machines integrate printing capabilities with label application. These machines can print variable information, such as barcodes, batch numbers, and expiration dates, on demand. The labels are then precisely applied to the products, ensuring real-time tracking and traceability. These machines are widely used in industries with constantly changing product information.

The Uniqueness of Automatic Labeling Machines

While the various types of labeling machines serve specific purposes, what sets automatic labeling machines apart from conventional manual or semi-automatic models is their ability to combine unmatched efficiency and precision in a single streamlined process. Below are the key features that make automatic labeling machines truly unique:

High-Speed Performance

Automatic labeling machines are engineered to handle high-speed production lines without compromising on accuracy. These machines can label hundreds of products per minute, reducing overall production time and boosting output significantly. The integration of advanced control systems ensures consistent label application with minimal downtime.

Versatility and Adaptability

Unlike conventional labeling machines, automatic labeling machines offer a high degree of adaptability to diverse products and label types. Quick and easy adjustments allow manufacturers to switch between products with varying shapes, sizes, and label materials without halting production. This versatility makes automatic labeling machines suitable for various industries, from cosmetics to pharmaceuticals and from food and beverages to chemical manufacturing.

Precision Label Placement

The heart of automatic labeling machines lies in their precision label placement capabilities. Advanced sensors and vision systems detect product orientation, ensuring labels are applied accurately and symmetrically on containers of different shapes and sizes. This precision reduces the risk of mislabeling, enhances brand reputation, and minimizes product recalls due to labeling errors.

Integration with Industry 4.0

Automatic labeling machines are at the forefront of Industry 4.0 integration. These machines can seamlessly connect with manufacturing execution systems (MES) and enterprise resource planning (ERP) software, facilitating real-time data exchange and tracking. This level of integration allows for better control over production processes, inventory management, and supply chain optimization.

Minimization of Material Waste

Automatic labeling machines are designed to optimize label usage, minimizing material waste. Precise label application and proper adhesive control result in reduced label overlap and misplacements, translating to cost savings for manufacturers. Moreover, some machines are equipped with label length detection systems, further optimizing label material usage.

In conclusion, automatic labeling machines have emerged as an indispensable tool in modern-day manufacturing and packaging industries. Their high-speed performance, precision label placement, adaptability, and seamless integration with Industry 4.0 technologies make them truly unique. As the demand for efficiency and accuracy continues to rise, automatic labeling machines remain at the forefront of revolutionizing production processes, providing businesses with a competitive edge in today’s dynamic market. Whether it’s enhancing product visibility or ensuring regulatory compliance, these machines play a crucial role in driving success and growth for industries worldwide.